If you’re like me, a CNC system is on your DIY wish list. I’m happy to report, I just purchased a used CNC mill system and thought I’d share a few details, as I expect you’ll be interested.

The system is called “Mostly Printed CNC” or MPCNC and is described as “inexpensive, capable and expandable.” The specialty fabricated mechanical components of the CNC platform are rapid prototype fabricated parts.

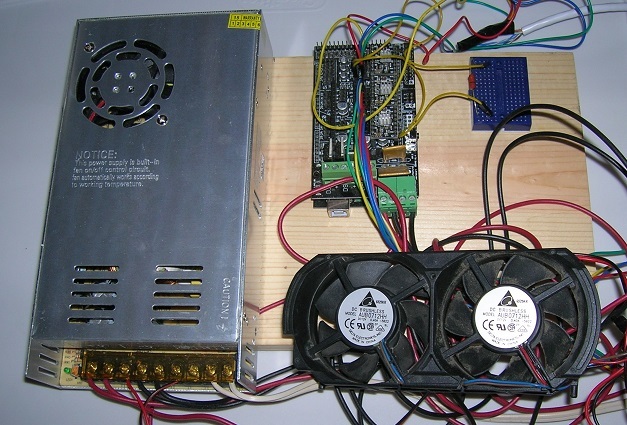

I’m in the process of building my own base for the CNC, so I don’t have the system running yet. Below is a picture of the system as purchased (less the base). The mill head is a Dewalt 660. This system will have a work area of 13”x36”.

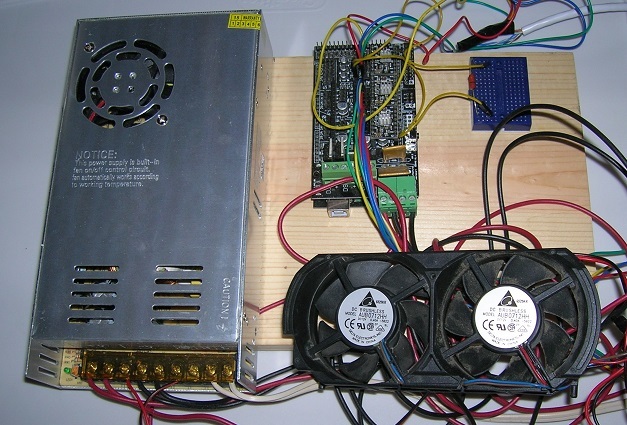

The electronics for MPCNC is based on an Arduino board. Here’s a picture of the power supply and Arduino board. (The only item not shown is a speed controller for the mill head.)

The software costs are minimal. The all-inclusive new system cost, (including purchasing the RP parts) is less than $600 from what I understand.

If you want to get more details, go to www.vicious1.com. This website has lots of good info and a user forum.

In the future, I’ll post my progress and details, if anyone is interested. In the long term, I expect that I will modifying the CNC system, replacing the mill with a laser for cutting and etching, which has already been done.

Lots to learn, should be fun.

Bill K.

What software do you plan to use? Fusion 360 is free now for no commercial uses and is an all inclusive CAD/CAM/Post processing software. Would be interested if anyone has made a post for it that works wit this system.

@Jacob_Edmond On the website under the specifications they list free software to use and Fusion 360 is one of the packages listed.

I haven’t scoured the site yet, but If they don’t provide a file for post processing the GCode, it might be a real pain.

A couple of days ago I finally was able to create a project in fusion 360 and export the GCode for the XCarve with Inventables gcode post processor. It’s not a simple process.

@Bill_K This looks really interesting. Using the pipes instead of Makerslide could make it more rigid than a machine like the XCarve. I’ll be watching to see how your experience is. I’m really interested in using the same tech to make a 3d printer.

I’m definitely interested in seeing what you do with it!

you can make your own post processor,machine shops do it all the time. Using a speedcontrol isnt good for a dewalt 660,you can kill the motor that way. better to use a small router.

@ Jacob: The cam software that came with the system is “Estlam.” This is not freeware, and appears to be quite capable. I haven’t gotten far enough along to try it yet.

Bill K

@Fazzman: The speed controller to be used is made for a router. I couldn’t find any related reports on failures. Your experience?