I found myself needing to make some turned tool handles. In the past I’d done this on one of my metalworking lathes but it is a huge pain to clean all the dust and chips out of the machine so I decided it was time to get a simple wood lathe. I thought about buying one from Harbor Freight or Grizzly, but the problem I kept running into was that the length I needed required quite an expensive lathe and I wasn’t about to pay several hundred dollars or more for that, especially when I don’t need or want to turn bowls. My requirements were a swing of only about 2 inches but at least 36 inches between centers. 1/3-1/2 HP would be plenty.

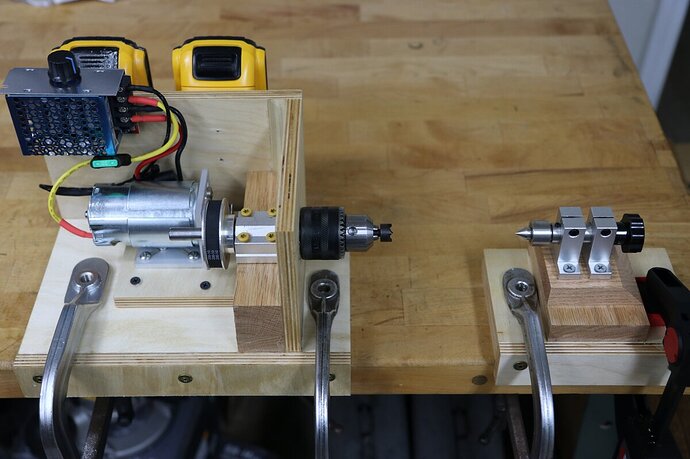

I ended up coming up with this idea which I thought was pretty clever: I built a separate headstock and tailstock using parts from Amazon with the bases made from plywood. They are placed on a stout workbench, secured with clamps, and then the workbench becomes the bed of the lathe. There is a small amount of adjustment on the tailstock quill but otherwise it can accommodate different size workpieces just by moving the parts on the workbench and re-clamping them. All said and done it cost me about $100 plus some scrap wood, and it works extremely well.

The tailstock is very simple. It is one of these from Amazon mounted to a plywood base, with a second guide rod support added so I could screw it down in four places instead of just two.

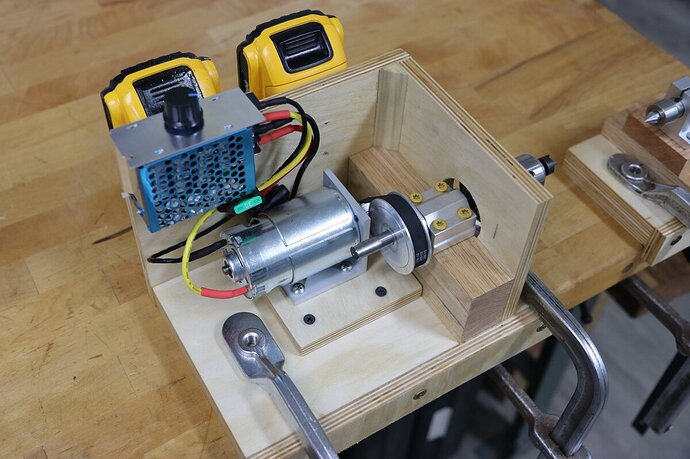

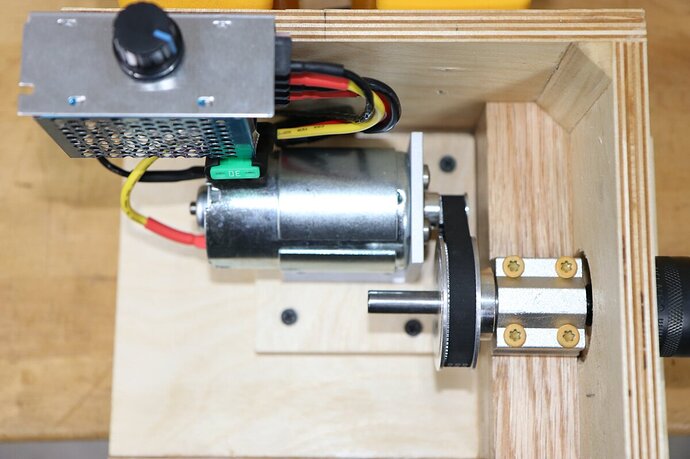

The headstock is built around this assembly:

https://www.amazon.com/dp/B08DXXY9J4

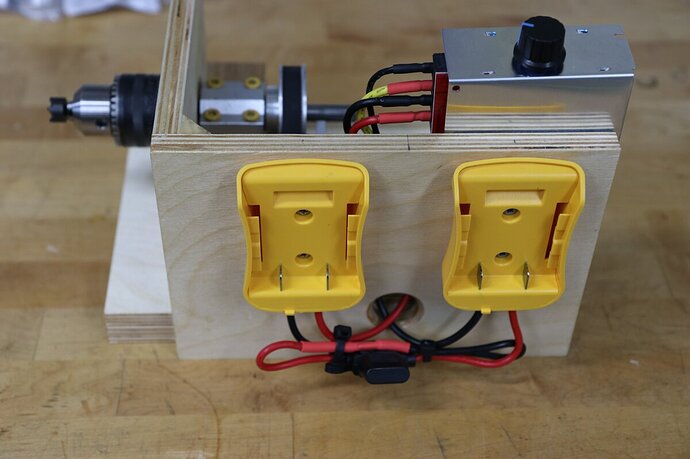

The power source is a 400W 48V 997 DC motor I found on sale for $20. It drives the spindle via 10mm wide GT2 timing belt, 20t pulley on the motor and 80t on the spindle for 4:1 reduction. All of those were cheapie parts from Amazon. Power is two Dewalt 20V max packs in series using “power wheels adapters”, and speed control is via a 30A PWM unit, also from Amazon.

The base of each is 1" thick birch plywood and has space for clamps. There is a lip under the front edge of each base so they align on the edge of the workbench. I made a couple different tool rests from scrap wood that likewise can be clamped to the workbench.

Performance was great. The motor has plenty of power–maybe not for a big bowl but it’s more than enough for the swing I want. It’s obviously light duty but it seems well sized for the work I am doing, and I think it’s a great idea for doing turning on a budget and maybe it will help inspire some people. The same idea could be upscaled for doing larger work.