@Jacob_Edmond I have an insulated / heated 2 car garage, inside another 4 car garage. Basically, the previous owners added another garage on. I leave the inner door closed, because it’s winter in Colorado. So I have a garage in my garage. And ask away.

1500 sqft! My garage shop is about 200 sqft. I feel so inadequate

P.S. I live in the Canadian Rockies and frequently have to work below freezing point with the door open because there is not enough space to handle larger pieces of wood with the door shut.

Thats pretty sweet. I felt lucky with my 2 car garage, because its a real 2 roll up door garage, larger than most built these days on newer homes. I’m starting to feel cramped in it as I fill it with tools and storage though. I need to measure it and see what the actual square footage is.

Edit: I’m estimating a little over 400 sq ft.

So the inner climate controlled one is your workshop essentially? I guess you’ve got plenty of room to spread out when need too.

@Graham_Howe don’t feel bad, everyone’s work space is sacred. For 10 years my work shop was 150 sqft. And the ceiling was 5 feet 11 inches, and I’m 5 feet 10 inches felt very confined.

@Jacob_Edmond yes, sums it up. A store was going out of business and I bought all those gondola shelves and the outer garage is lined with those as well, to bring it back around to workspace storage, to keep the thread on track.

Yeah I don’t feel too bad really, I am getting the work space to be reasonably organised. It is a bit annoying that space rather than budget are preventing me from getting some of the tools I want though (cabinet saw, band saw, jointer).

Yeah me too. Although my drill has some wobble, needs to be picked up by Bosch for fix.

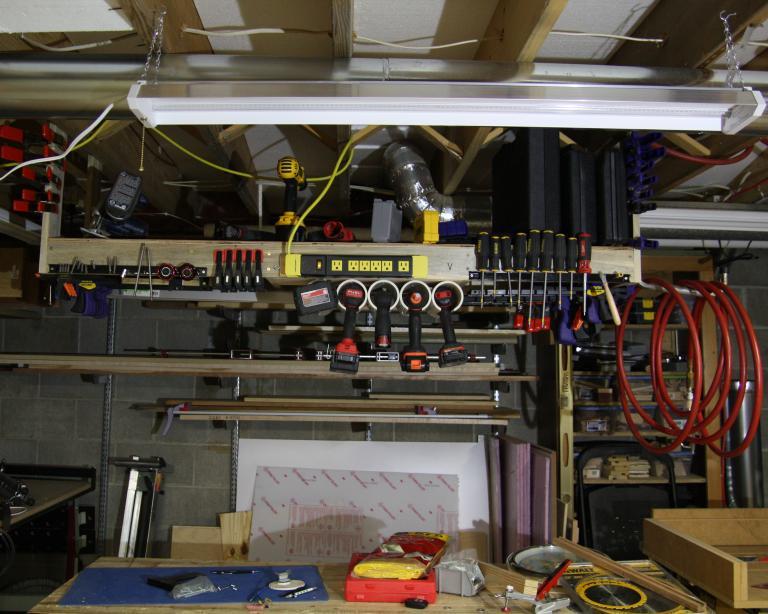

Since the my unfinished overhead bench storage seems to be the hero shot of the post over on the blog featuring this thread, I figured I’d show a finished picture.

I know this is bad lighting, but I had to turn off all the lights behind it to even get a shot of it. This is above my workbench. I routed power and air to it for easy access. I try to put all the tools I use regularly on it. You can see my most used power tools hanging below with my clamps. I have a couple of magnetic strips to hold screwdrivers and bits. Above I have cordless saws and nail guns.

Turn 180 degrees and you have all my parts and hand tool storage. I have racks in the rafters designed to accept plastic shoe boxes.

Here’s my wood “library” I have about a dozen different species of wood that I use for accents and small projects.

Very Very Impressive I’ve been meaning to do that overhead door storage thing for a while but I have little room above my door.

When I moved in about 40 years ago - most of the basement already had a raised wood floor and finished ceiling. It had been dug out as part of the original house and then as part of an addition. The older part (front of the house was dug out deeper - so there was more headroom (about 8 feet) to install machinery - my band saw, table saw, larger jointer compressor etc. and to run a dust collection system. The rear section’s ceiling was lower (7 feet) - had been the prior owner’s shop and had pegboard installed along one long wall. I kept it for hand tools - and added 2 benches to compliment one that he left. If I had to do it again - the pegboard ( which became very congested ) would have been replaced with something else.

Again - not so much a unique idea - but more a notion that if you have a lot of items - then you should keep an inventory of what you have and where it is located. In a commercial setting we had several tool rooms - hundreds of feet of shelves, cabinets, racks, bins - stored tools, patterns, samples, cutters, parts etc. For the stuff we used often - we could lay our hands on it by memory - but for infrequently used items we tried to organize them by task, kept them together as much as we could in boxes bins or shelf locations - and then had a computerized (I remember a time when it was on paper) inventory giving us the quantity on hand, location and other information (cost basis, barcode if any, etc.). I adopted something similar - but a bit less complex for my home shop - where I’ve accumulated many tools that had been used more frequently - but now are in toolboxes, on closet shelves etc.

I don’t know how unique you can call this but I found a way to fit 4 of my 10,8V drills in a single L-box in stead of just 2 with the standard bosch inlays. This is just a layer cake of cardboard cut to fit the space between the drills. Very easy but somewhat time consuming.

Hmm, this doesn’t even seem to fit the workshop criteria either,…

Very cool. If you haven’t already, you should check out Kaizen Foam from www.fastcap.com . It would also work perfecty for those spacers between.

Cardboard like that cuts really nicely on a bandsaw…

I’ve thought about doing something similar inside my L-boxxes. One of these days, I’ll get a L-boxx2 for my 18v tools.

Look into making a hot wire cutter to cut foam. Very easy way to make perfect foam inserts.

There is also a foam cutter from Bosch - sort of works like an electric knife - with 2 serrated blades that move counter to each other. The blade come in different lengths to accommodate different foam thicknesses.

the foam suggestions are actually better. Does anyone have a suggestion for Europe? I found this on the German Amazon site but its pricey. That’s why I went for the cardboard.

http://www.amazon.de/gp/product/B00Y3OUZMM?keywords=sortimo%20foam&qid=1458759332&ref_=sr_1_1&sr=8-1

Did anyone try to cut multiple layers of cardboard with a jigsaw?

Bosch Blade T113A does a pretty decent job of cutting cardboard:

http://www.amazon.com/Bosch-T113A3-4-Inch-Knife-Jigsaw/dp/B001AHU5P2

If you want inexpensive foam - here in the US - you go to Home Depot and look at the various builder’s foam insulation. It cuts OK with a knife (a cheap serrated edge steak knife is OK for curved cuts) or with any number of variants of hot knives designed for EIFS.

http://www.amazon.com/s/ref=nb_sb_noss?url=search-alias%3Daps&field-keywords=eifs+cutter

Hot wire cutters used in crafts and floral work can also be used - but some of those are rather flimsy - so you have to take it slow.

For me the big problem with cutting Styrofoam is all the staic electricity generated along with all the little clingy pieces. When we ere cutting the stuff outdoors with a any sort of regular saw blade - the wind would take the stuff all over. We hit on using a Ridgid saw meant for fiber cement - hooked to a dust collector - and that was just OK for thin sheets:

Then we head about some circular knife-edge blades from a company called Bullet Tools - we found that they were OK when new - but they quickly dulled and were a bit scary to handle:

I have a number of different type of tape measures that I store under benches clipped to some flat aluminum stock. I cobbled these from scraps of wood and flat-stock from some other jobs. The flat stock has just as easily been purchased at HD or Lowes:

I probably should have included a list of some of the oddball tape measures that I have accumulated over nearly 50 years. Here are links to a few that are still available:

Modular Spacing Tapes:

http://www.bontool.com/product1.asp?P=ECONSPACINGTAPES

Center Finder Tape:

http://www.amazon.com/50035-1-Inch-25-Foot-CenterPoint-ProTape/dp/B0000CEZ8X

Metric System Tape:

http://www.amazon.com/Fastcap-PMMR-TRUE32-True32-Reverse-measuring/dp/B0130E8JQY

Fastcap Burn-1

Fastcap Story Pole

and

Fastcap Timberframe

http://www.fastcap.com/estore/pc/viewPrd.asp?idproduct=46120

Hultafors Talmeter

Johnson Stud Squared

Komelon Engineer

Komelon Stainless Steel

Komelon Roller

http://www.amazon.com/s/ref=nb_sb_noss?url=search-alias%3Daps&field-keywords=KOMELON RB25

Tajima Metric